After digging and drying the clay, one needs to decide which method to use to make the clay.

Method one: levigating (slaking with water to separate large particles from smaller).

Using a large volume of water and agitation to separate out the heavier particulate (sand, small stones) from the lighter clay particle and light organic material (roots, leaf matter, decayed wood).

For my purposes, I am using a concrete mixing tray. I use about 20 gallons of water to 5 gallons of clay-bearing material. After the initial introduction of the clay material to the water, I stir it around and then let it sit for about 2 days. This gives the material time to absorb water and to break down.

At this time, I begin to stir up the material to create a clay-heavy slurry that I then dip out and pour through a screen.

Once the material has been stirred and agitated, I scooped out the slurry and passed it through a screen. The screen is used to catch any small pebbles or organic matter like leaves, sticks, or roots.

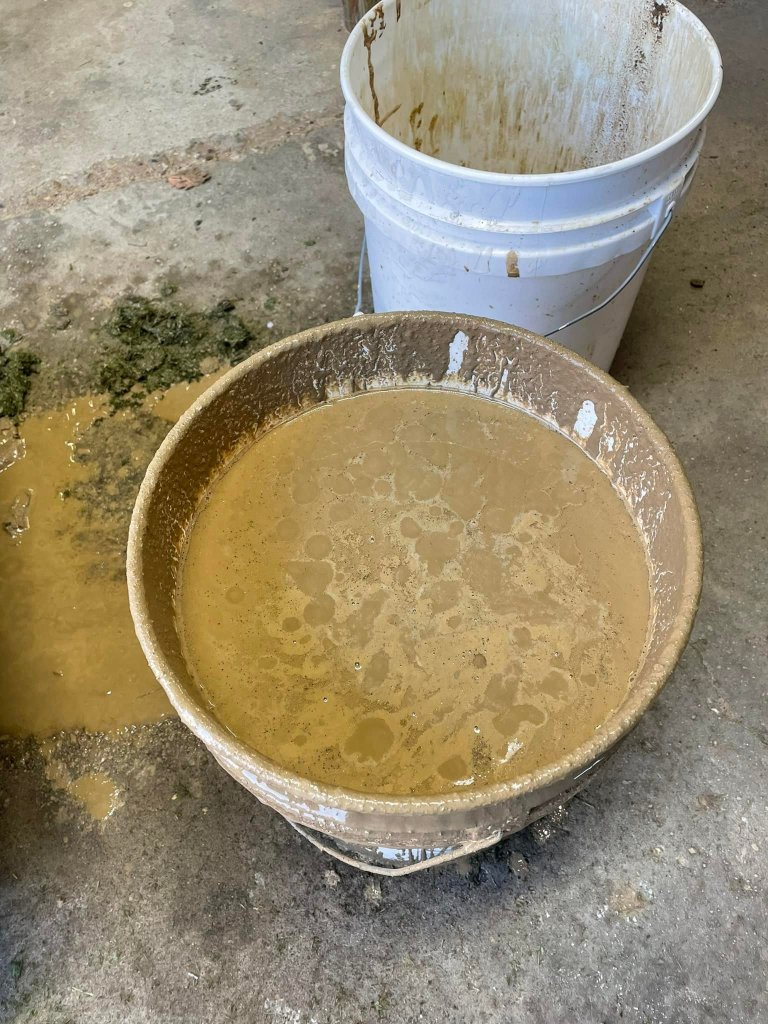

This is the slurry about an hour after being screened. This will need to settle for a couple of days. Once settled, the clear water can be poured off from the clay slop.

This is the clay slop from the bucket. I have poured the slop out onto a painters tarp to help pull moisture out. At this stage, it looks a lot like fresh cow manure.

This is the clay after a couple more days of drying and being turned to avoid excessive dryness on the edges and too wet in the center. The clay could be used to make pots at this point.

Method two: dry mixing.

Method two: dry mixing. Taking the raw material as dug from the ground, place some on a hard surface and grind. As the material is ground to a powder, move it to the side and continue grinding until you have as much as is needed for the project.

Begin to add small amounts of water to bring the ground material together. The material; will get sticky for a little bit, but as the water is absorbed by the clay, it will become more manageable and less sticky.

Once all the loose, ground material is brought into a moist ball, let this set while wrapped in damp cloth or plastic for a couple of hours. This resting time will let all the particles absorb the moisture and become a more homogenous clay to be used for making a pot.